AI Deep Learning Inspection & Smart Factory

To evaluate the quality of the deep learning model, we perform a variety of testing and validation processes, which are to see how effectively the model performs on a given task and to evaluate whether it has been properly generalized.

Smart Factory & AI Inspection

Measurement

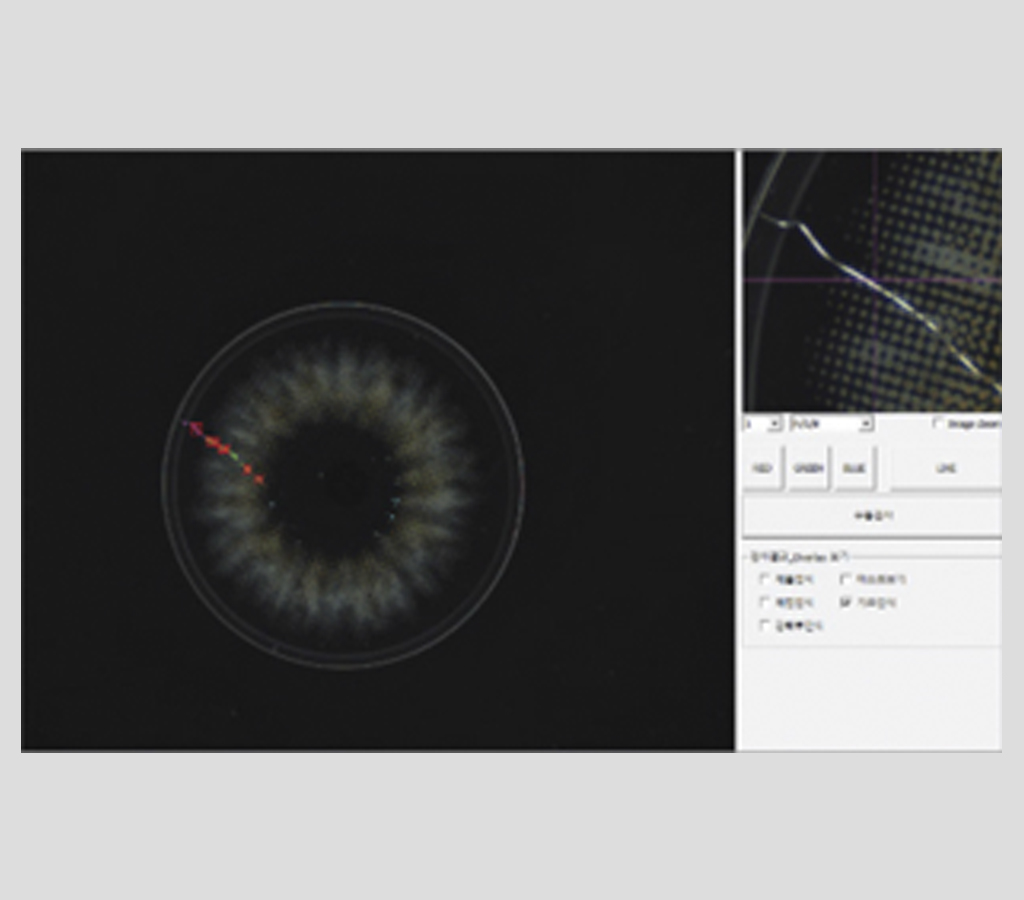

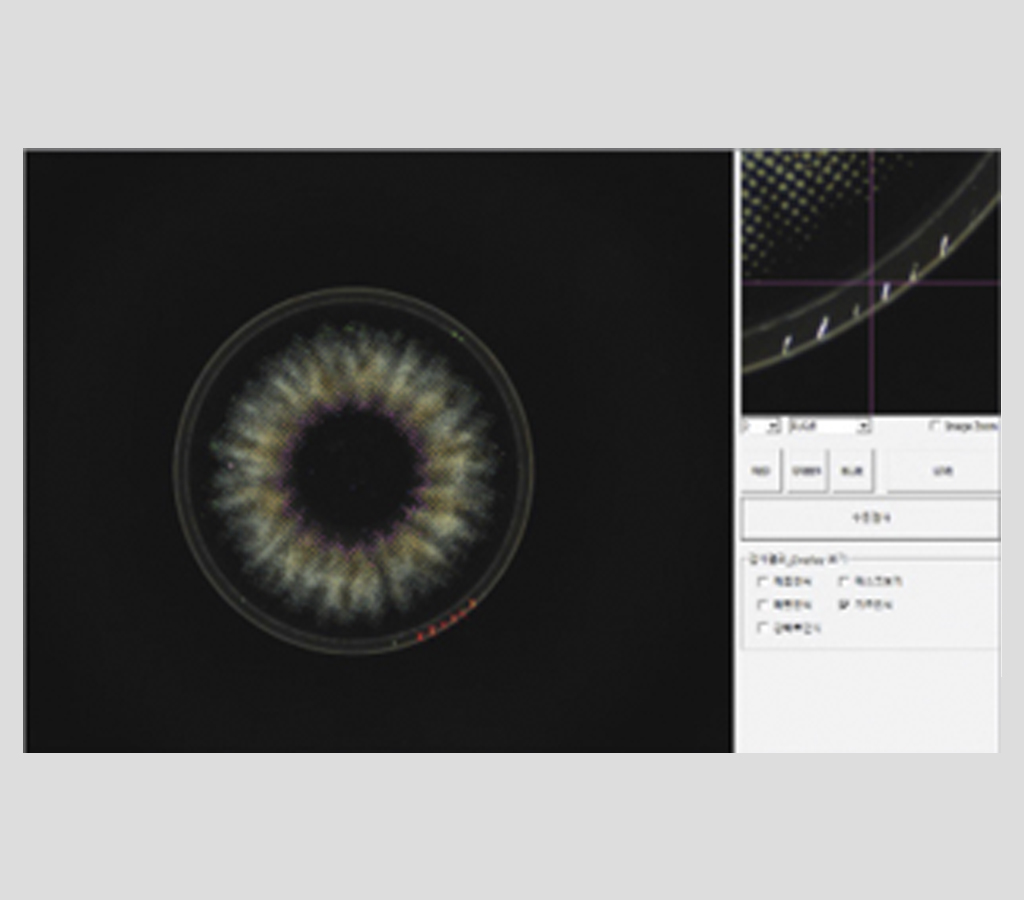

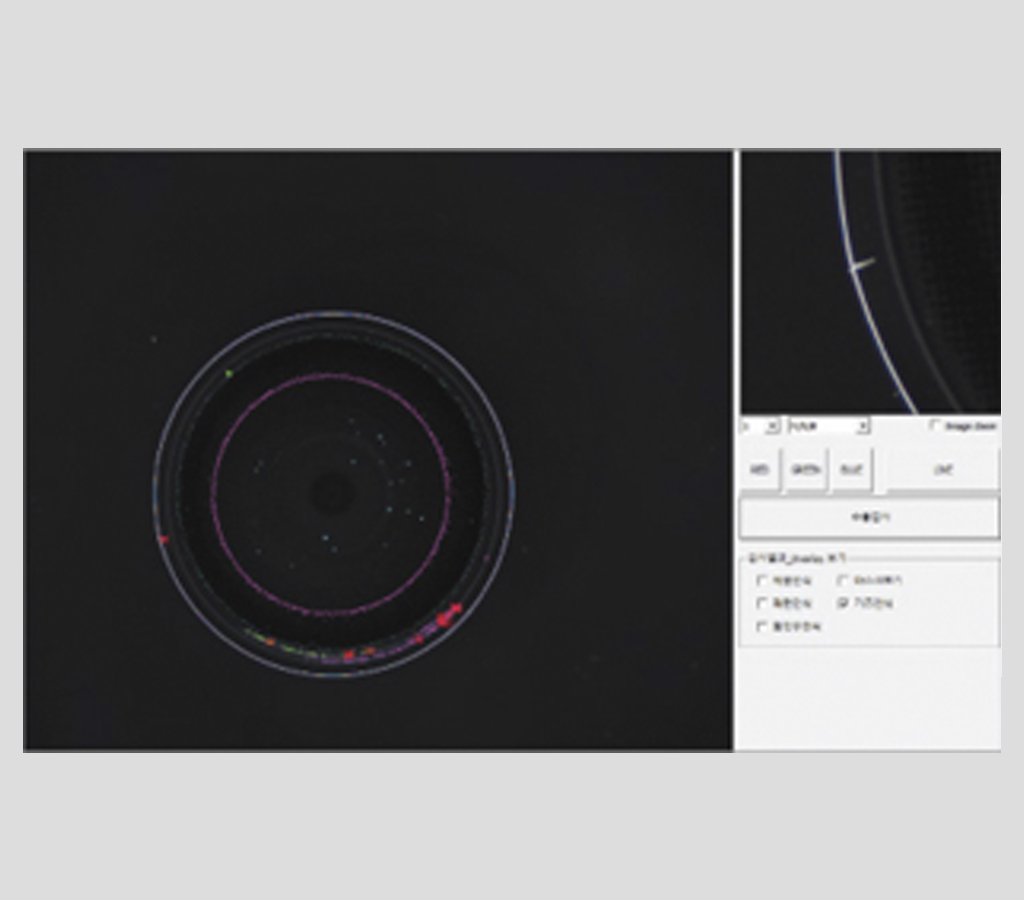

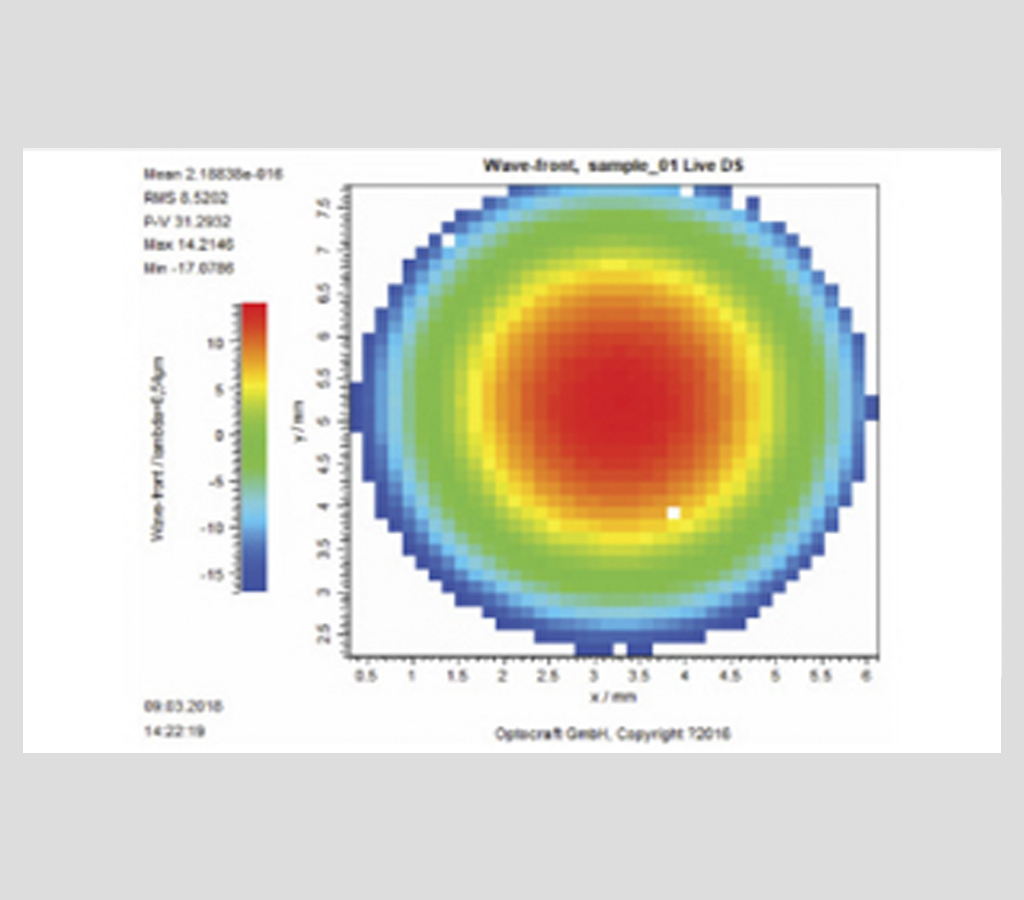

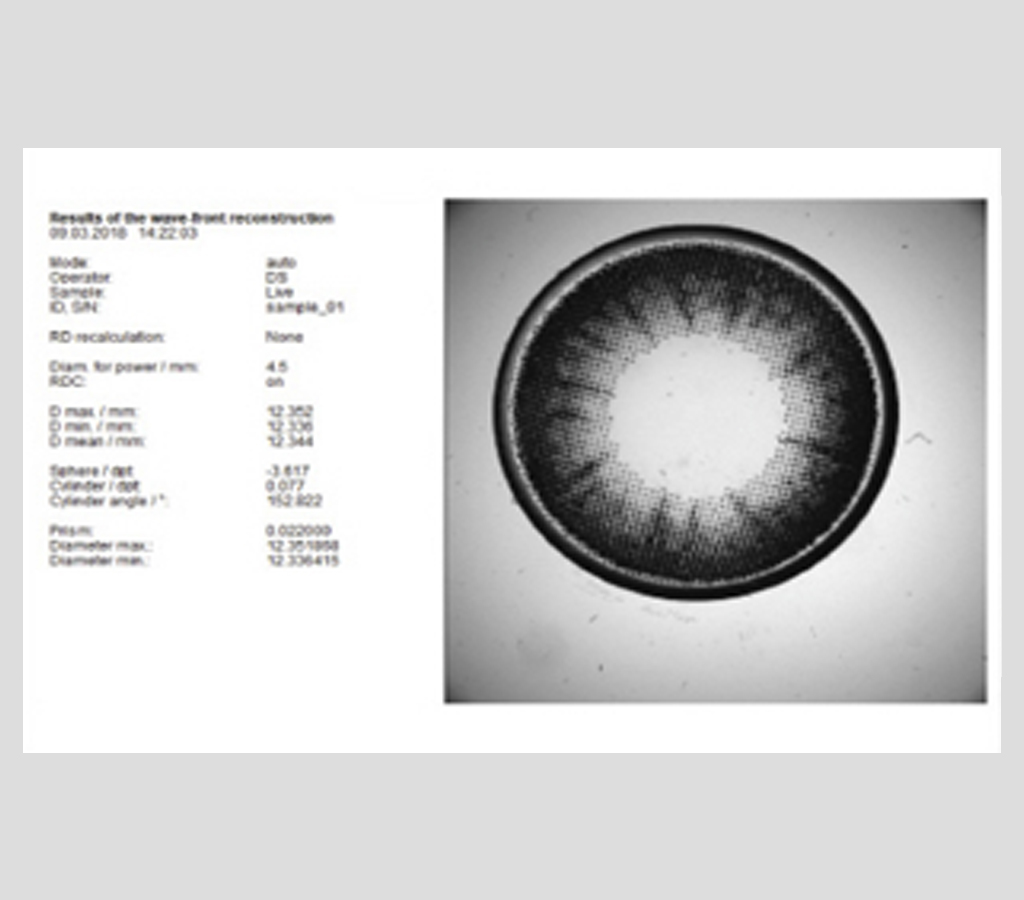

contact lens tester

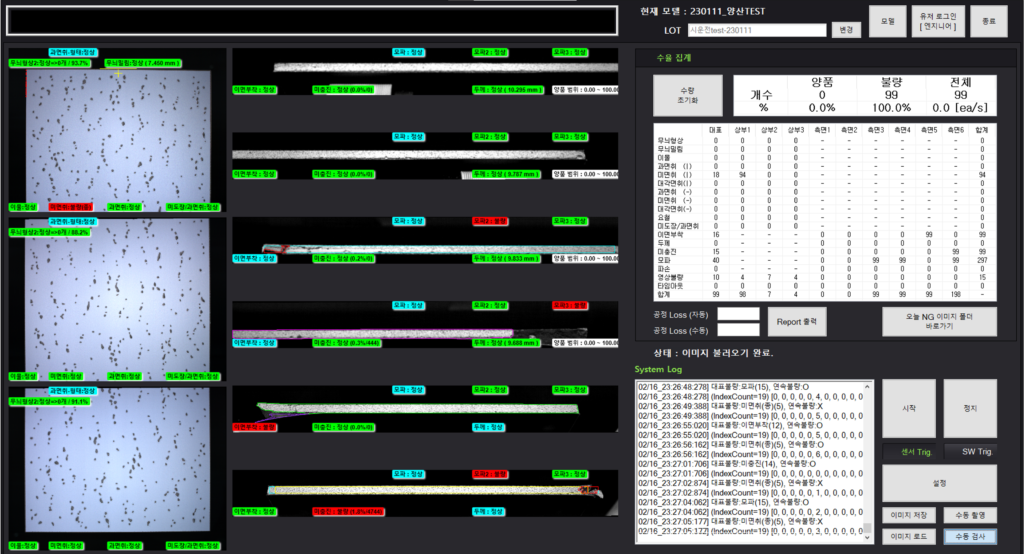

■Contact Lens Inspection System

■ Model : CLI-100

- • Subject to inspection: Contact lens (dry)

• Inspection Item

– Lens Edge: Tear, Tear, Foreign Body, Scratch

– Optical areas: foreign objects, scratches, bubbles

– Pattern area: Air bubbles, scratches, large printing defects, concentration of printing patterns

– Others: Poor lens molding

• Examining Options

– Lens Power and Diameter

– Lens CT (thickness)

• Inspection period: 1ea = within 4 seconds

• Detection power: 50um or more

• Defect classification: can be classified by item after defining inspection items

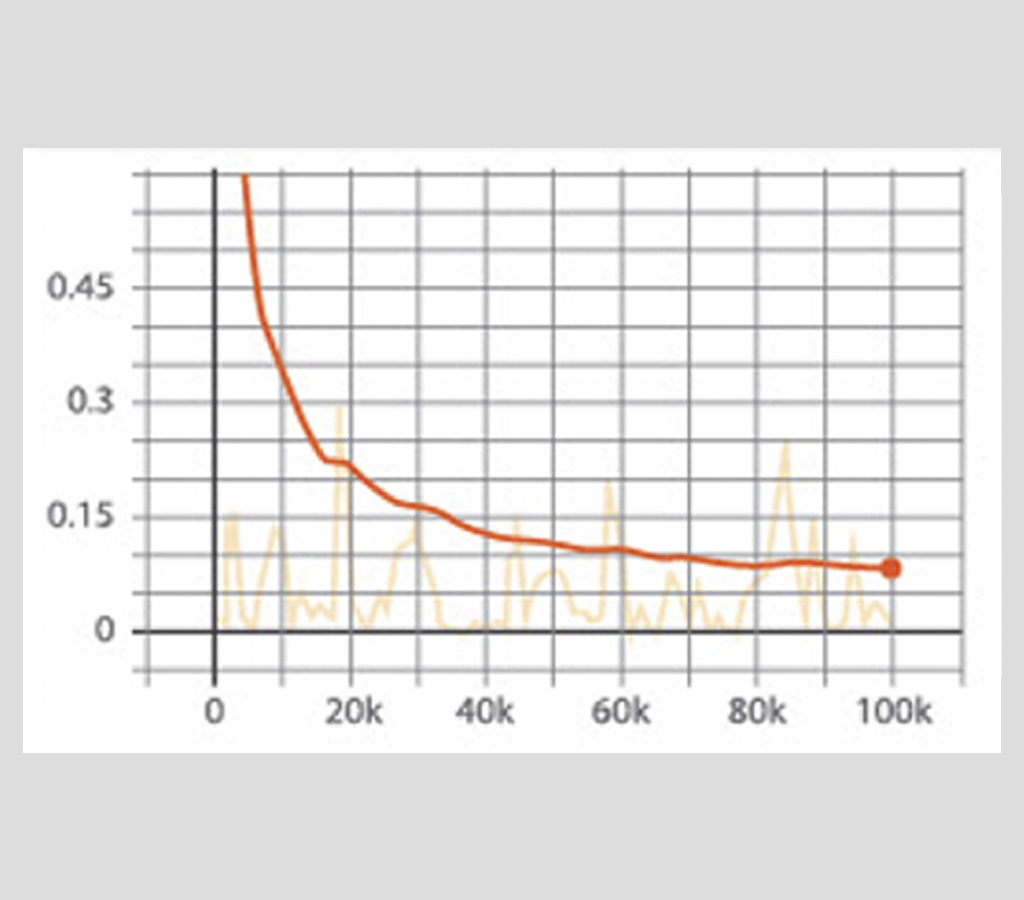

• Error rate graph

• Verification table

No | Category | Average | Result |

1 | Scratch | 99.97% | detectable |

2 | Broken | 99.95% | detectable |

3 | extraneous material (Point) | 99.96% | detectable |

4 | extraneous material (thread) | 99.93% | detectable |

5 | curve Print | 99.97% | detectable |

6 | 99.98% | detectable | |

7 | void | 99.96% | detectable |

8 | Backlight | 99.97% | detectable |

Measurement

Appearance inspection machine for building materials

■ Appearance inspection machine for building materials

summary

• Purpose – Appearance inspection of finished gypsum products being transported on the conveyor belt.

• Inspection details

Appearance inspection all together (pattern size, pattern pushing, defrosting, foreign matter, stain, damage, etc.)

Result processing: Automatic defect classification (loaded), alarm in case of continuous failure

• Configuration

Industrial optical system, inspection PC, and conveyor set for defect classification

• Optical System Configuration

Depending on the inspection point and product size

FOV 350*300mm standard: More than 0.4mm can be detected

• Organization System Configuration

4-section composition = Inspection unit + Transfer unit + Selection unit + Transfer unit

Sorting unit: Screening inverter + defective transfer unit + loading inverter + loading unit

• System Features

You can inspect Flying Mode without stopping.

High-resolution, high-speed inspection is possible.

Real-time quality control is possible.

Measurement

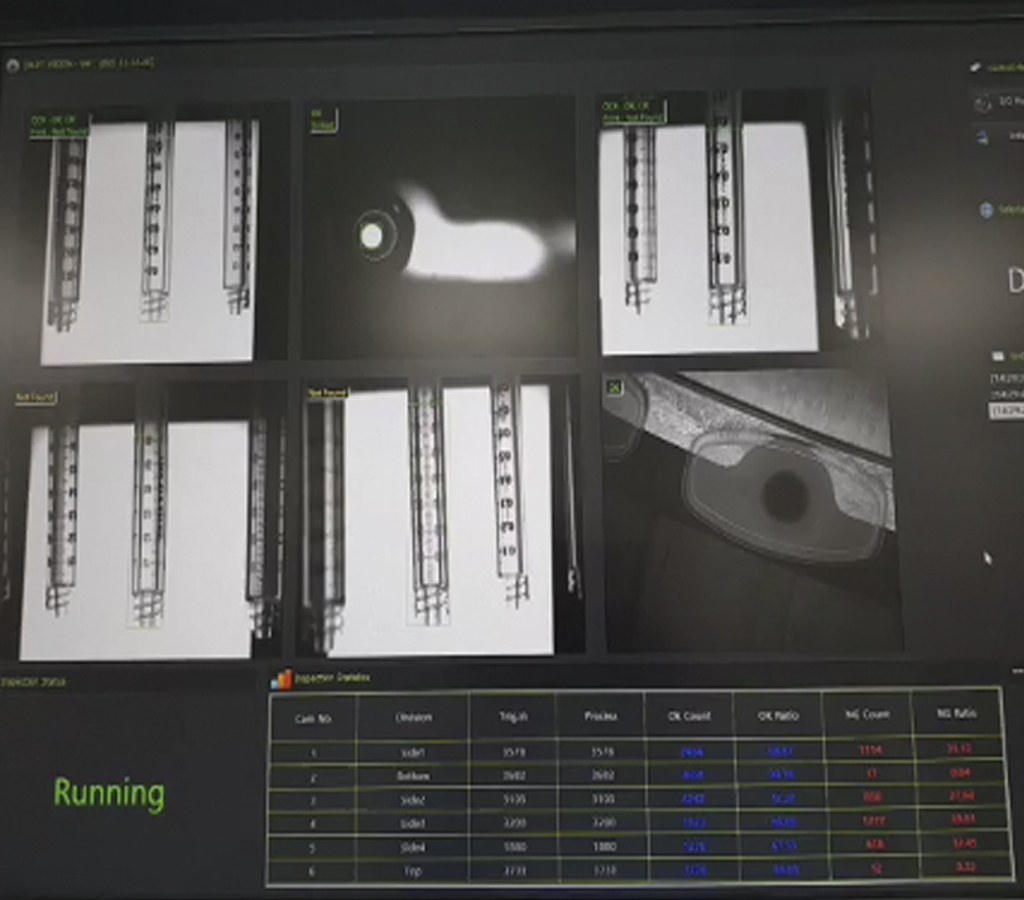

Injection, mold appearance inspection machine

■ Injection, mold appearance inspection machine

■ Characteristics

1. Application:

- Automotive injection products, medical injection products, food injection products, etc..

2. Inspection items

- OCR: Separation of similar characters between numbers and English

- Shape (=molding) defective

- Geez, scratch

- Breaking

- Black spots, foreign objects, etc

(a medical syringe)

(Food container)

Measurement

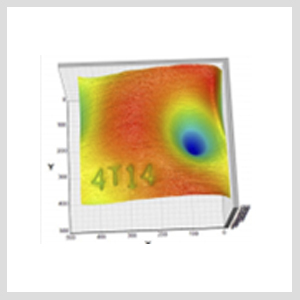

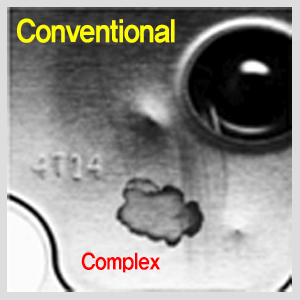

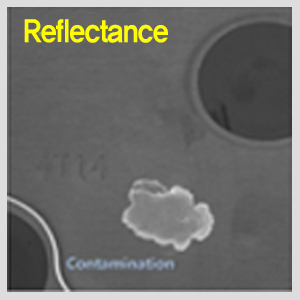

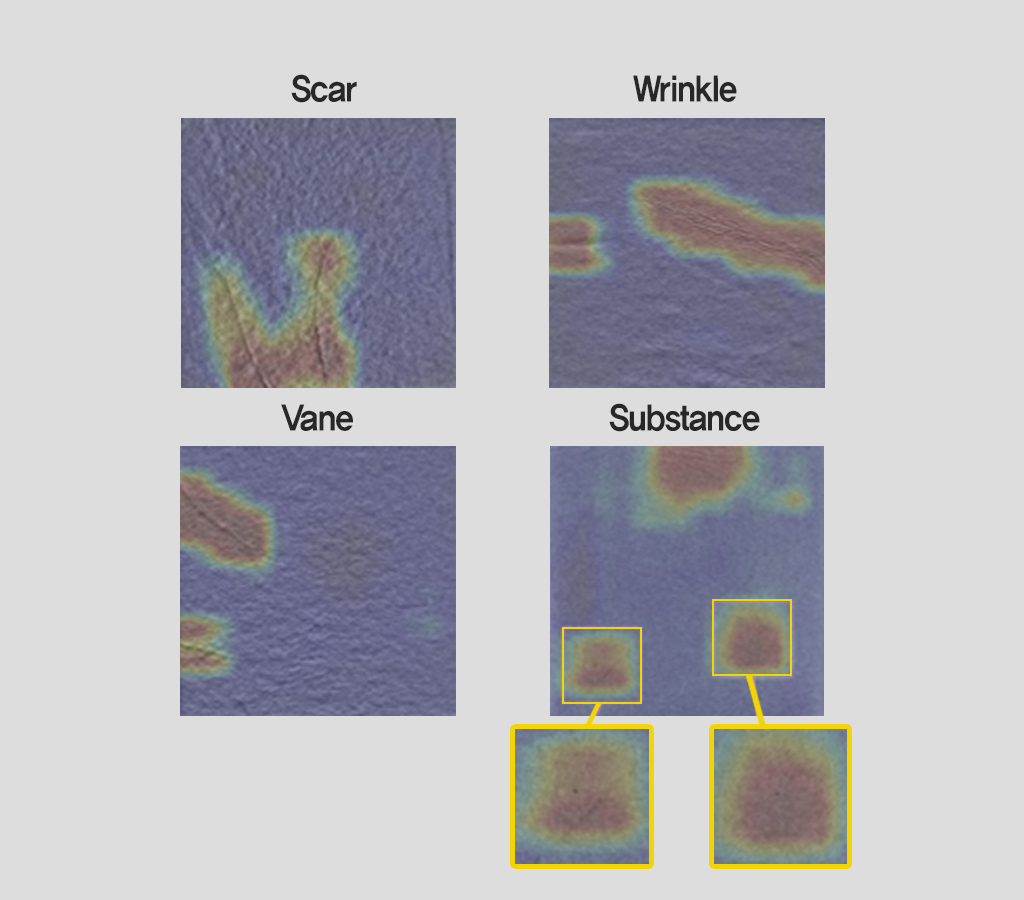

a natural leather checker

■a natural leather checker

■ summary

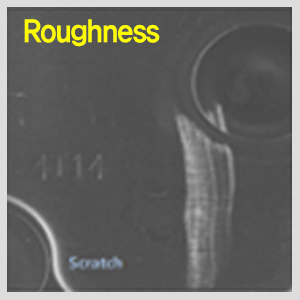

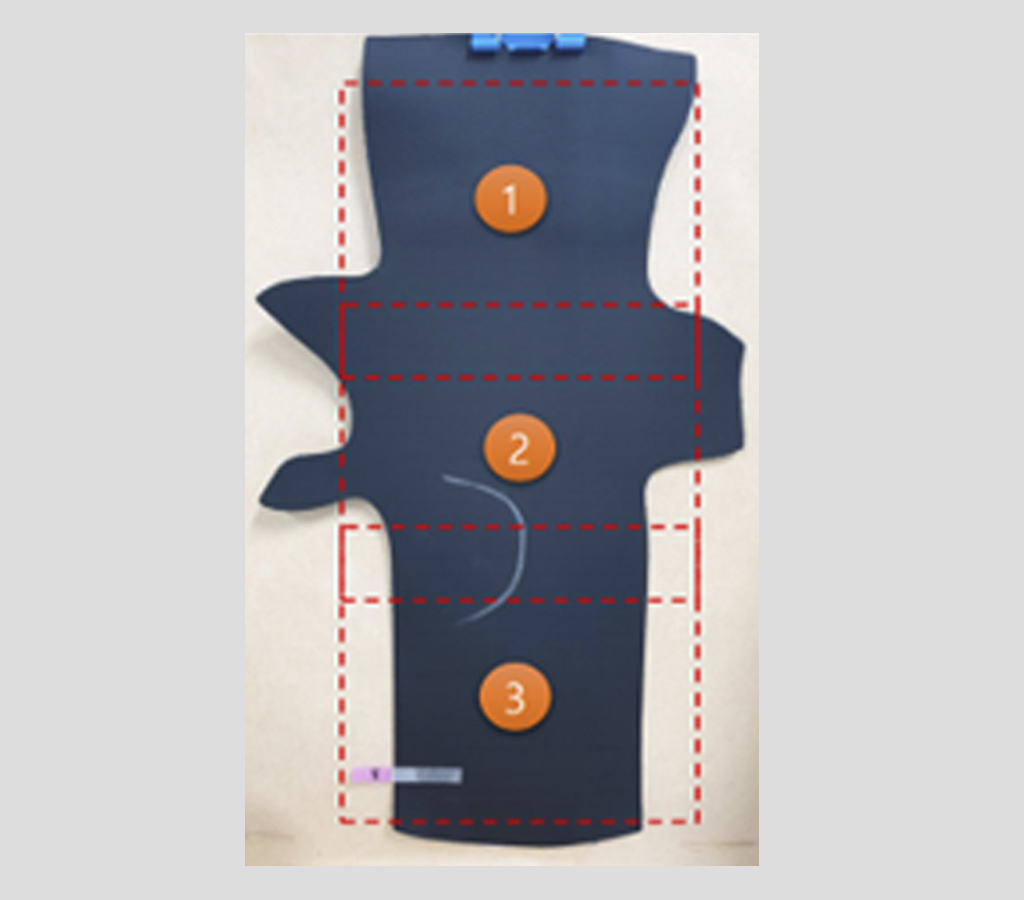

“Surface Prpperty Image”

– New Technology: Measurement of surface top frame information

1. Features of the sensor

2. How to acquire data

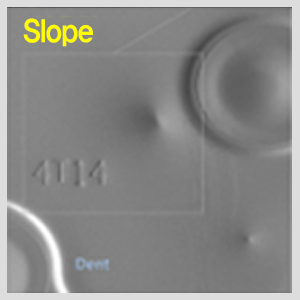

1. A total of 27 resulting images taken from one sample 3 split

2. Seven images were stored in each folder (x1, X2, x3) in the inspection area of each split

3. Results Data

1) REF: Reflectance data

2)_INH, INV: Slope horizontal/vertical data

3)_IN2: Absolute value data for gradient horizontal & vertical

4)_RGH, _RGV: data in the horizontal/vertical direction of the lugger

5)_RG2: Absolute value data for horizontal and vertical dimensions

3. How to acquire data

4. AI Learning Results

No | Configuration | Specification |

1 | Applied Products | pre-consulted natural leather cuttings |

2 | Size | Min: 180mm / Max: 432mm |

3 | Thickness | 1.3T + 0.1T |

4 | elongation rate | Product that doesn't matter if you expand by 7% |

5 | a foreign body | a product without foreign substances attached |

6 | Concept | 4Line/1System equipment: 2x2 Set configuration for improved accessibility and workability |

7 | FFU | None. |

8 | Foreign substance | Manual management. |

9 | How to put the product in | Manual input to Load Magazine |

10 | Product Collection Method | Product Collection Method |

11 | How to Transfer Products | Motor transfer and pick-up using Cyinder Direct contact with Vacuum Pad (adsorption pad) |

12 | Change the model | Manually changing the interval between Load/Unload adsorption pads Automatic change by recipe change (apply axis only with Motor) |

13 | How to stretch a product | 5% elongation to the long axis, 2% elongation to the vertical axis The vertical extension is in the shape of a semicircle |

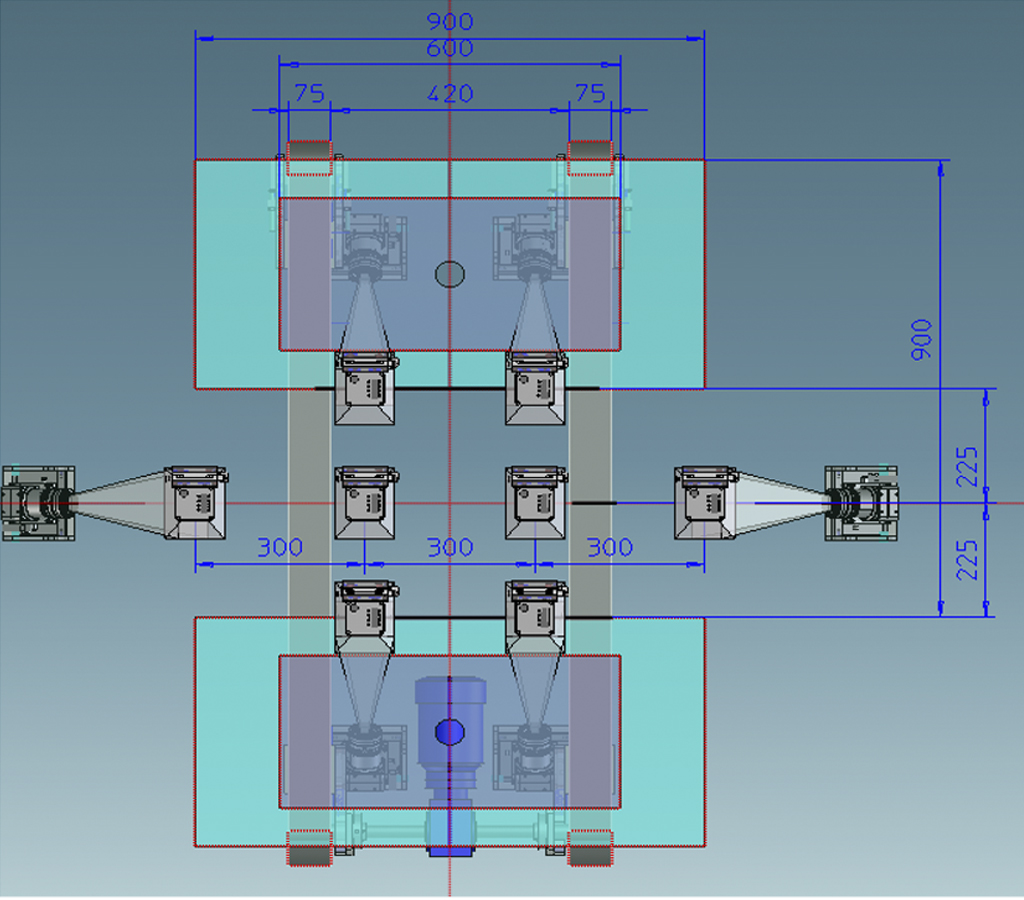

Measurement

Inspection of automotive electronic parts

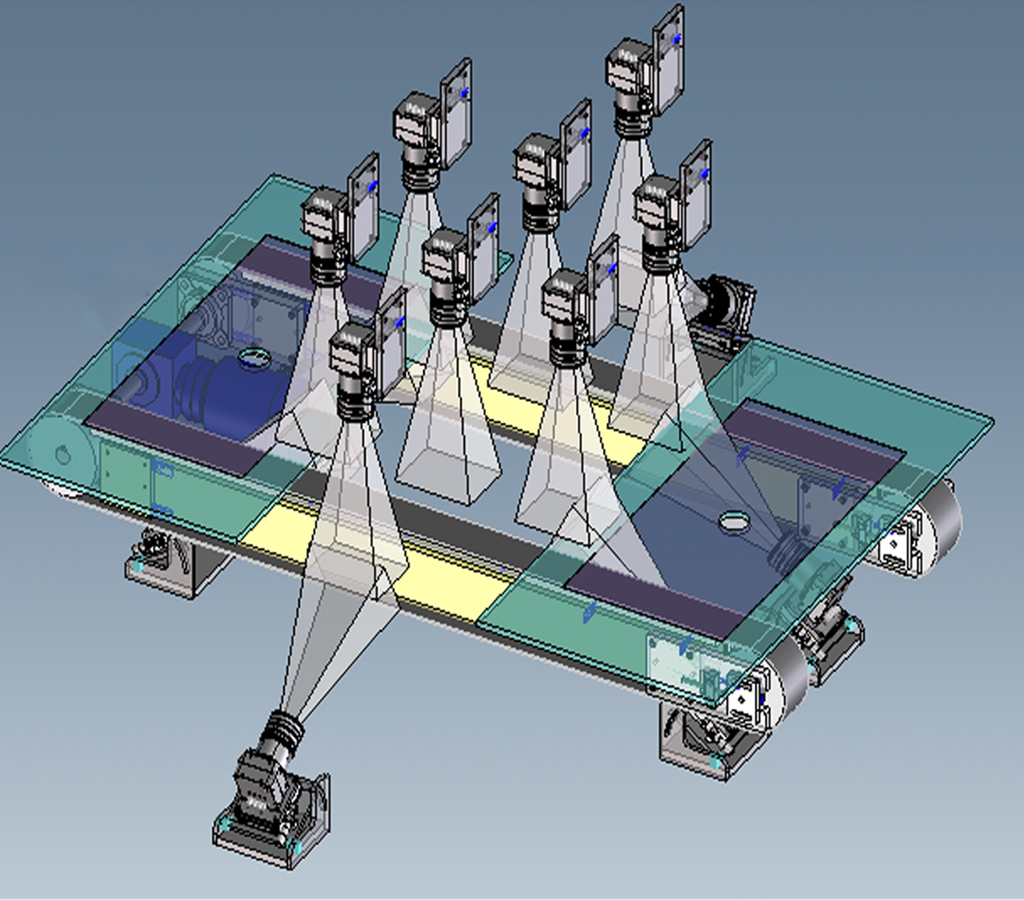

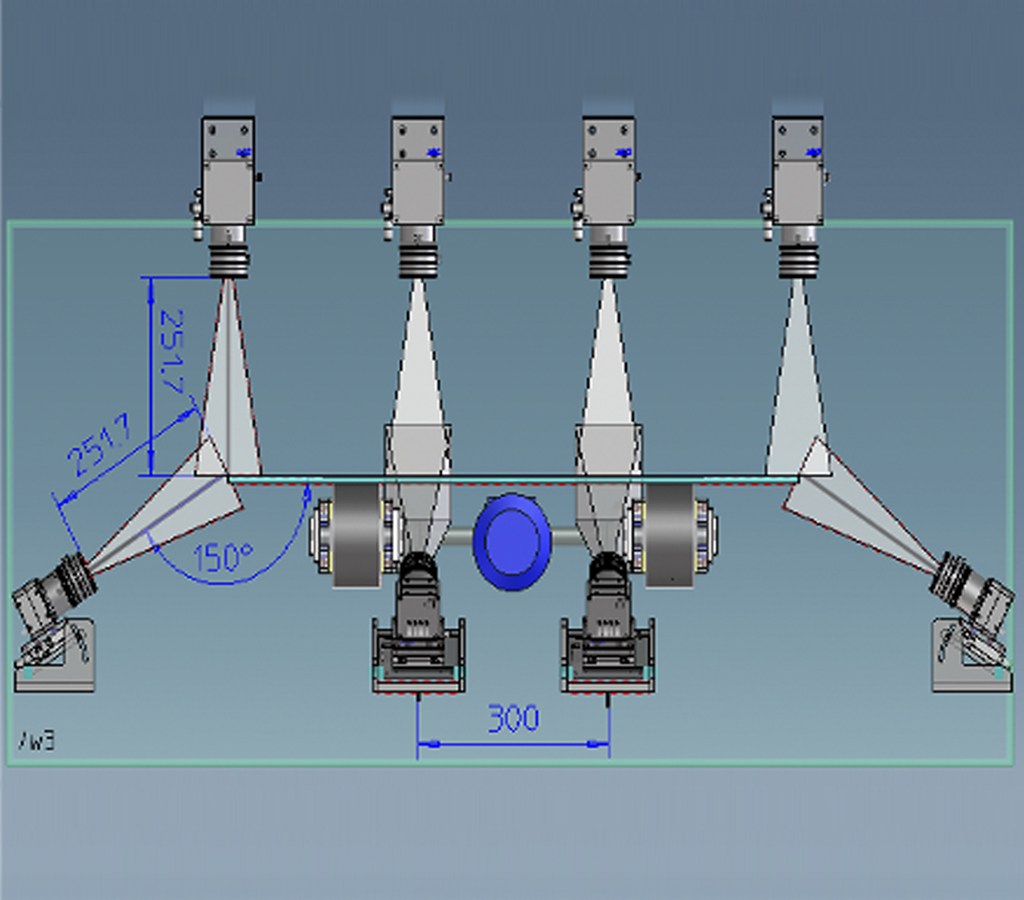

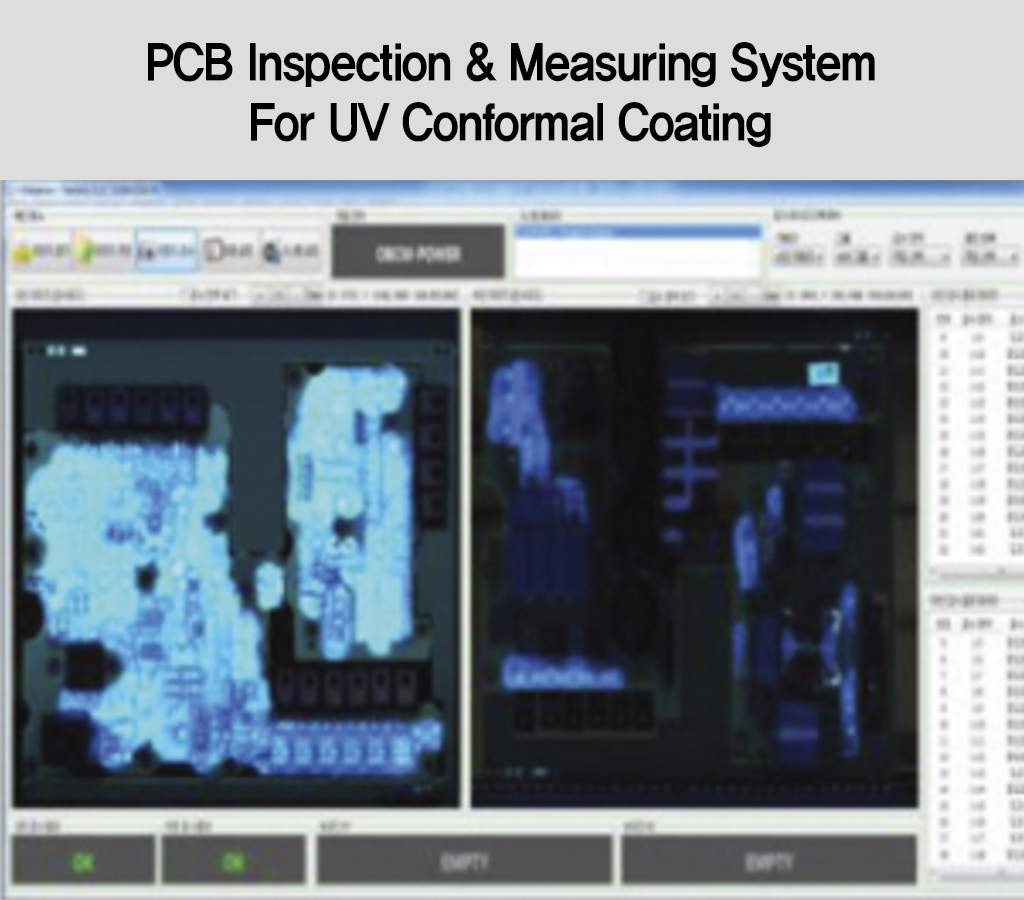

■ PCB Inspection & Measuring System For UV Conformal Coating

■ Model : AUI-350

• Subject to inspection: Automotive electronic components, electronic PCB

• Inspection Item

– Inspection of electric vehicle electrical PCB UV Coating Application Area / Non-coated Area

– Electric Vehicle Full-length PCB UV Coating Application Area / Thickness Measurement

Double-sided simultaneous examination

Option : Magazine Buffer

• Inspection period: 1 ea = 30/S

Detection power: UV coating test 100um or more

UV Coating Thickness 20um-500um

• Defect classification: can be classified by item after defining inspection items

– Simultaneous Double-Sided Inspection

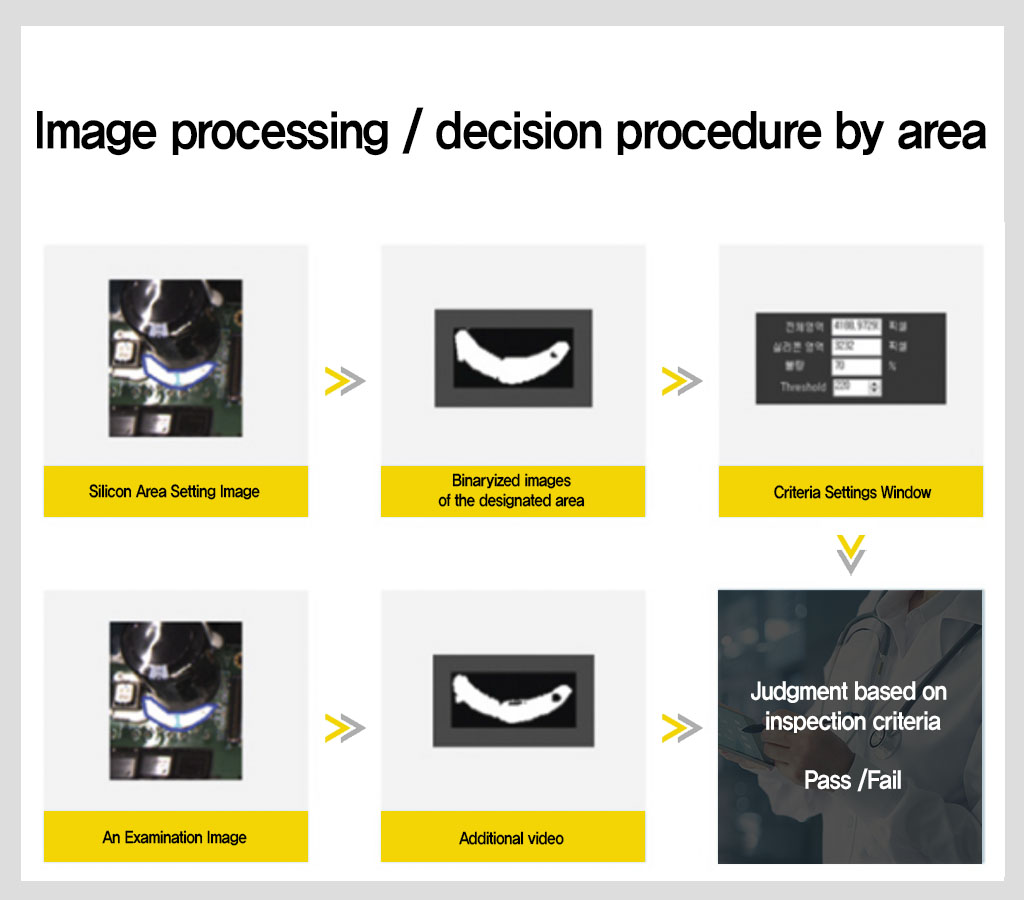

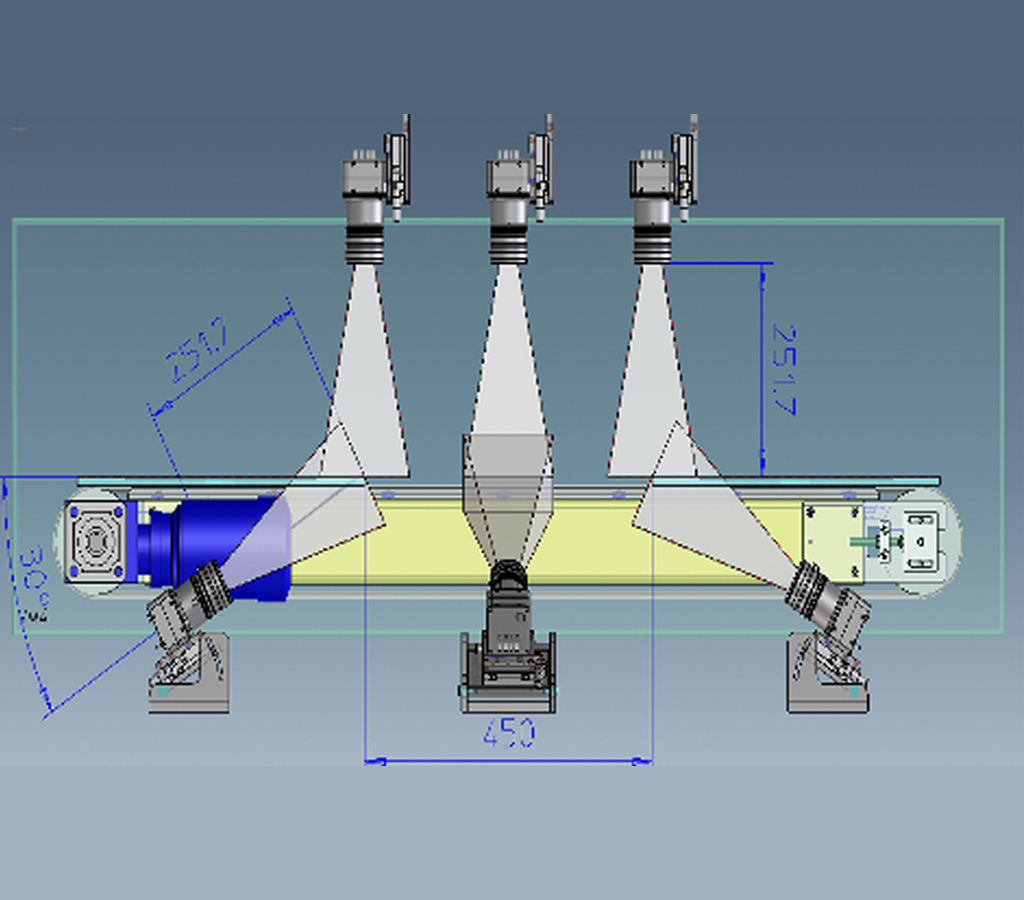

■ PCB Inspection & Measuring System For UV Conformal Coating

■ Model : ASI-350

• Inspection target: Automotive electronic components, ceiling PCB

• Inspection Item

– Inspection of electric vehicle electrical PCB Silicone Coating Application Area / Non-coated Area

– Report the MES after determining the amount of money

• Option: silicone application thickness measurement, weight measurement after application

• Inspection period: 1ea = 10/

• Detection power: Silicone application 100um or more

• Defective classification: After defining inspection items, classification can be made by item